creep of steel at high temperatures|tertiary creep steel : service The creep of steel at high temperatures, by F. H. Norton webNa mesma tela em que inseriu o código de convite, toque em “Copiar” para adicionar o número à sua área de transferência ou compartilhe diretamente em apps como WhatsApp e Instagram. Toque .

{plog:ftitle_list}

webLocated on Highway 10 north of The Pas, in the Community of Opaskwayak, the Aseneskak Casino is easy to find and can be accessed by road, air and rail. Northern .

The creep of steel at high temperatures by Norton, F. H. (Frederick Harwood), 1896-An icon used to represent a menu that can be toggled by interacting with this icon.The creep of steel at high temperatures, by F. H. Norton TLDR. The fitting results demonstrate that non-Newtonian viscosity functions significantly enhance the fitting quality and the numerical investigations suggest the superiority .

Metals and alloys can be designed to withstand creep at high temperatures, usually by a process called dispersion strengthening 2, in .

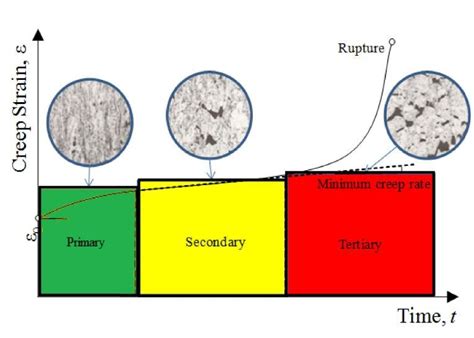

Creeps are characterized as time-dependent permanent deformations that occur under constant stress at elevated temperatures. The material composition determines the onset of creep. For example, steel . The assessment of creep notch sensitivity, creep crack incubation and growth, and creep damage accumulation during creep-fatigue transients, are practical examples requiring a knowledge of creep-ductility.Materials for High Temperature Creep Resistance • Metallic materials commonly used for high temperature service include: Stainless steels - Alloys based on Fe + carbon + Chromium (+ . Based on a series of creep curves of Q550, Q690, and Q890 high-strength steels obtained from creep experiments, a new three-stage creep model, together with creep .

requirements of high-temperature service. This booklet discusses factors that should be considered by engineers facing problems in designing equipment for high-temperature service. The characteristics that make some of the stainless steels particularly useful in high-temperature environments are described, and typical engineering data are .THECREEPOFSTEEL ATHIGHTEMPERATURES y BY rrH:NORTON Babcock&WilcoxResearchFellow, AfassachiisettsInstituteofTechnology FirstEdition SecondImpression McGRAW . The austenitic stainless steel 316 is of current interest as structural material for the future Gen IV nuclear power plants operating at high temperatures. Although 316 steel grades have been studied for the service conditions of current nuclear and other conventional applications, improved data and models for the long term high temperature . As shown in Fig. 2 (a) and (b), the uniaxial creep curves for 20Cr32Ni1Nb steel were evaluated under various conditions of temperature and stress. The results of these creep tests are presented in Table 2.A similarity in the creep deformation behaviour was observed at temperatures of 1163 K (890 °C) and 1223 K (950 °C), where the creep strain was observed .

2004 triumph bonneville how much compression test

The P92 steel is known to possess the maximum creep strength of the ferritic heat-resistant steels for boiler components. The T91 steel has been widely used in power plants. A recent study published in the Journal of Constructional Steel Research investigated the high-temperature and post-creep response of structural steels. The authors conducted creep tests in the 300 to 800 °C temperature range, using stress levels in the 0.4‐1.1 yield strength range. In a high-temperature environment, creep rupture is the major failure mode of metallic materials. 316L austenite stainless steel has been widely used in nuclear reactors for its extraordinary creep strength and corrosion resistance. In this work, the uniaxial tensile deformation and creep behavior of 316L austenite stainless steel at elevated temperatures .

Research investigations on the creep behavior of several categories of structural steels at elevated temperatures have been conducted. According to the creep tensile test results of several American structural steels, including ASTM A36 and ASTM A572 which have yield strength of 248 MPa and 345 MPa, Harmathy [14], Brnic et al. [15] and Kodur and Aziz [16] . For example, high-temperature creep-resistant ferritic steels achieve optimal creep strength (at 923 K) through the dispersion of yttrium oxide nanoparticles. However, the oxide particles are introduced by complicated mechanical alloying techniques and, as a result, the production of large-scale industrial components is economically unfeasible. The creep of steel at high temperatures by Norton, F. H. (Frederick Harwood), 1896-Publication date 1929 Topics Steel Publisher New York [etc.] McGraw-Hill book company, inc. Collection northeastern; blc; americana Contributor Northeastern University, Snell Library Language English Item Size

Mechanical properties and creep behavior of Q460E continuous casting slab were studied by means of uniaxial tensile tests on a Gleeble-3800 thermomechanical simulator from 1000 to 1100 °C. The high-temperature creep constitutional equation was derived based on experimental data. The parameters in the equation were calculated by using the regression .

time of materials at high temperatures. Creep is a performance-based behaviour since it is not an intrinsic materials response. Furthermore, creepis highly dependent on environment including temperature . Figure 8.1 Comparison of creep and stress rupture tests c) Steel melts at ~1500°C=1773 K and is known to creep in steam plant applications . The creep response of the 17-4PH martensitic age-hardening steel in H1150 state was investigated at 427 and 482 °C. Hardness measurements of the heads of the creep samples demonstrated that the . Martensitic creep-resistant P92 steel was deformed by different methods of severe plastic deformation such as rotation swaging, high-pressure sliding, and high-pressure torsion at room temperature. These methods imposed significantly different equivalent plastic strains of about 1–30. The aim of this paper is to present a systematic study on high-temperature creep and post-creep response of structural steels. A wide range of stress levels (0.4‐1.1 of the yield strength) was adopted to span all possible loads when conducting creep tests at temperature range from 300 to 800 °C.

Long ago, Andrade and Orowan suggested that primary creep at high temperatures obeys a power-law behavior with an exponent of 1/3: $$ \varepsilon = bt^{1/3} + c_{1}. $$ (5) . Oehlert and Atrens performed creep studies on steel at ambient temperature where the applied stress is below the macroscopic yield stress. The lower head of reactor pressure vessel (RPV) will endure a great temperature gradient above the phase transition temperature, and the creep and fracture will be the primary failure mode for the RPV material in such a situation. The interrupted creep tests were performed on a typical RPV material, SA508 Gr3 steel, at 800 °C. The microstructure of different creep . Fig. 6 shows the full process curves of high-temperature creep of the 1960-HSSW. According to the variations in the creep curves, the high-temperature creep of the steel wire is divided into three stages: transient creep stage, steady-state creep stage, and tertiary creep stage. As shown in Fig. 5. In the transient creep stage, an initial creep .

tertiary creep steel

higher temperature creep rate

From experimental creep rates of high temperature alloys, it is found they can be classified into three types: with creep rate decreasing only, with creep rate deceasing firstly but accelerating after a certain time, and with creep rate increasing slowly but accelerating after a certain time. . Creep constitutive equations for a 0.5Cr 0.5Mo 0 . The creep test results of AH4 and 9Cr-ODS steel showed that 9Cr-ODS steel has superior creep rupture strength at high temperatures, such as 900°C and 1000°C, which correspond to accident temperatures. These results can be seen from the equivalent stress LMP graph in Figure 6(b). Although the 9Cr-ODS steel has lower strength than PNC316 at the . Earlier studies about creep behavior at high temperature were focused on normal strength concrete (NSC), high strength concrete (HSC) and high-performance concrete (HPC). Anderberg and Thelandersson [18] are among the pioneers who studied creep of concrete at high temperature. They studied NSC with quartz aggregate and water to cement ratio (w .

Results of creep tests of two Fe-27 at. % Al-based alloys with additions of 2.7 and 4.8 at. % of niobium conducted in the temperature range from 650 °C to 900 °C in the authors’ laboratory are . The production of a 9 per cent Cr martensitic steel dispersed with nanometre-scale carbonitride particles using conventional processing techniques is reported, which should lead to improved grades of creep-resistant steels and to the economical manufacture of large-scale steel components for high-temperature applications. Creep is a time-dependent mechanism of .

Low values of n at higher temperatures (800 and 900 °C) indicate that diffusion-based mechanism might play a role during high temperature creep of the steel. It can be noticed from Fig. 7 that the creep rates at 900 °C are much higher compared to that at 800 °C. The creep behavior of the 12Cr1MoVG steel at high temperatures has been perfectly described by means of long-time creep tests and mathematical modelling. Minimum Creep Rate Versus Applied Stress .

Therefore, information on the high temperature creep behavior is needed for a better understanding of the mechanical behavior of the new alloys, their practical applications, and the comparison with conventional alloys. . (ASME SA-213/SA-213M grade T92) and 9Cr-0.5Mo-1.8W-V-Nb steel pipe for high temperature service (ASME SA-335/SA-335M grade . Tensile creep deformation of 12Cr1MoV steel is controlled by diffusion creep at NaCl-35%KCl salt environment with 600°C (2) Creep loading temperature has a great influence on the hot corrosion behavior of high-temperature alkali metal chloride salt. Under the same loading stress, as the temperature increases, the degree of hot corrosion deepens.

2004 triumph bonneville how much on compression test

Browse all Fracture Case CS2 skins and knives. Check mark.

creep of steel at high temperatures|tertiary creep steel